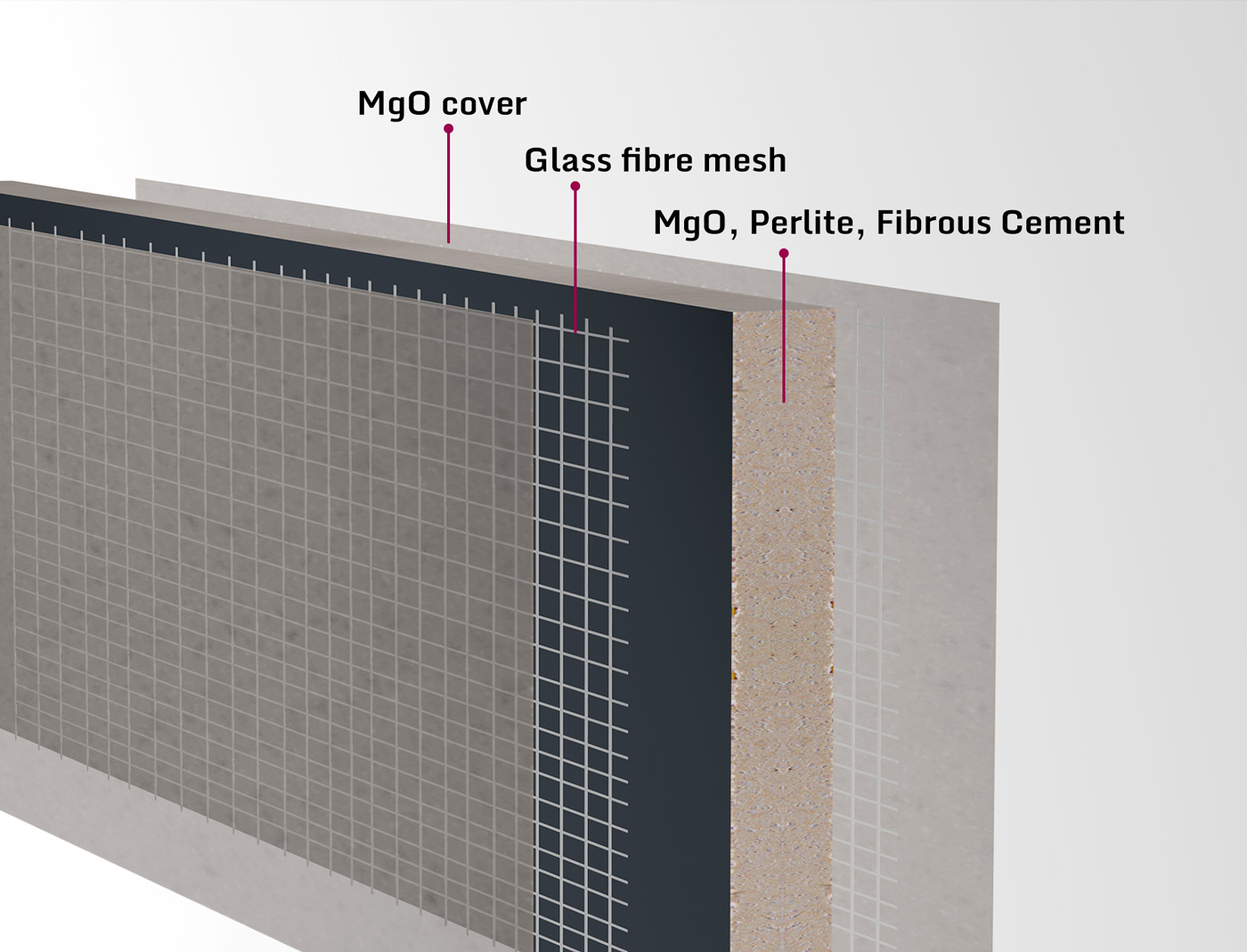

A classical magnesium board is a sandwich board consisting of the core from powdered perlite, surrounded on both sides with a mesh from glass fibre and magnesium layer MgO or magnesium-cement layer, which is often reinforced (in a dispersed manner) with cellulose fibre with the addition of other derivatives of magnesium compounds, such as magnesium chloride – MgCl2 or magnesium sulphates.

WHAT IS

A MGO GREEN MAGNESIUM BOARD

MgO Green board components:

MgO - magnesium oxide

50%

Magnesium chloride

25%

Fiber cement

15%

Perlite

8.5%

Others (e.g. cellulose)

1%

Glass fibre

0.5%

The application of MgO Green magnesium boards

The application of magnesium boards can be similar to gypsum and cardboard boards, OSBs or fibre and cement boards. The boards are used for all types of claddings of internal and external walls, partition walls, SIPs (structural insulated panels), acoustic panels and wherever the investors want to provide a special facility protection against fire, mould, decay and fungi. They can be easily plastered, glued, tiled and painted.

- Sandwich panels and SIP

- Dry buildings

- Frame construction

- Building facades

- Roofs

- Floors, ceilings and walls

- Increased humidity sites

- The construction of cellars, attics and lofts

- Insulation of warehouses and garages

- External casing of air conditioning and ventilation systems

- For fire-resistant doors, cable routes

- Fire walls and partitions

- Advertising boards

- Chimney decorations

- Arched and decorative elements

- Acoustic products

Comparsion

MgO Green board to similiar materials

| MgO | Gypsum Board | Cement Board | Plywood | O.S.B. | |

|---|---|---|---|---|---|

| Flame Spread | 0 | 15 | 0 | High | High |

| Smoke Developed | None | Low | None | High | High |

| Water Resistand | Yes | No | No | No | No |

| Mold/Mildew Resistant | Yes | No | Yes | No | No |

| Thermal/R Value per M | 0,155 | 0,23 | 0,4 | 0,3 | 0,25 |

| Impact Strength | High | Low | Low | Medium | Medium |

| Weight kg/m2 | 10 | 11,7 | 15,1 | 7,8 | 9,8 |

| Combustibility | None | Facing Burns | None | Burns | Burns |

| Structural | Yes | No | No | Yes | Yes |

| Environmental | High | Poor | Medium | Medium | Poor |

| Freeze/Thaw | Good | Poor | Good | Good | Good |

| Finish Interior | Tape/Paint | Tape/Paint | Provide Cladding | Provide Cladding | Provide Cladding |

| Finish Exterior | Render/Cladding | Interior Only | Render/Cladding | over sheath & vapour barrier | over sheath & vapour barrier |

Documentation

- Technical Data Sheets

- Technical Approval MgO board

- Hygienic certificate